Equipotential Bonding with Metal Stand Lock Bar Terminal Block is an advanced electrical connection device engineered to maintain equal potential across connected electrical equipment and systems. This innovative bus bar prevents electrical failures and hazards due to potential differences, ensuring safety and reliability in various electrical systems. It plays a crucial role in mitigating risks associated with lightning strikes, static electricity, and other potential electrical hazards, while optimizing current distribution and enhancing system stability.

|

ItemNo |

MJTB034 |

|

Contact Material |

Brass |

|

Termination Method |

Screw Down |

|

Working Temperature |

-40℃ - 110℃ |

|

Material |

Polyamide Housing |

|

Inserts |

Brass |

|

Screws |

Steel,Zinc plated |

Advantages of Equipotential Bonding with Metal Stand Lock Bar Terminal Block

1. Material: Brass-clad terminals, providing excellent conductivity and durability.

2. Design: Secure screw-protected switches for primary connections, ensuring safe and reliable electrical connections.

3. Functionality: Maintains equal potential, preventing electrical failures and hazards due to potential differences.

4. Construction: Robust design suitable for both domestic and industrial power distribution applications.

5. Protection: Effective in preventing electrical hazards caused by lightning strikes, static electricity, etc.

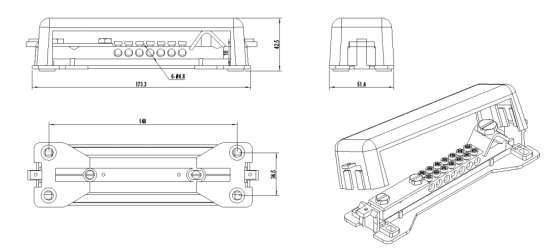

Equipotential Bonding with Metal Stand Lock Bar Terminal Block General Specifications

| ItemNo | Brass w x h | Holes | L | H | W | Ø1 | Ø2 | Screw Size | PCS/CTN |

| mm | mm | ||||||||

| SP034-01 | 14×10 | 7 | 173 | 42 | 51.5 | 5.8 | 3.8 | M5.0 | 50 |

| SP034-02 | 14×10 | 11 | 173 | 42 | 51.5 | 5.8 | 3.8 | M5.0 | 50 |

Application of Equipotential Bonding with Metal Stand Lock Bar Terminal Block

· Domestic Power Distribution: Ensures stable and reliable electrical connections in residential electrical systems.

· Industrial Power Distribution: Suitable for primary connections in industrial electrical systems, providing enhanced safety and reliability.

· Lightning Protection Systems: Mitigates risks associated with lightning strikes, ensuring the safety of electrical equipment.

· Static Electricity Control: Prevents hazards due to static electricity, protecting sensitive electronic devices and systems.

· Current Distribution Optimization: Enhances the efficiency and stability of electrical systems by optimizing current distribution.

Our hours