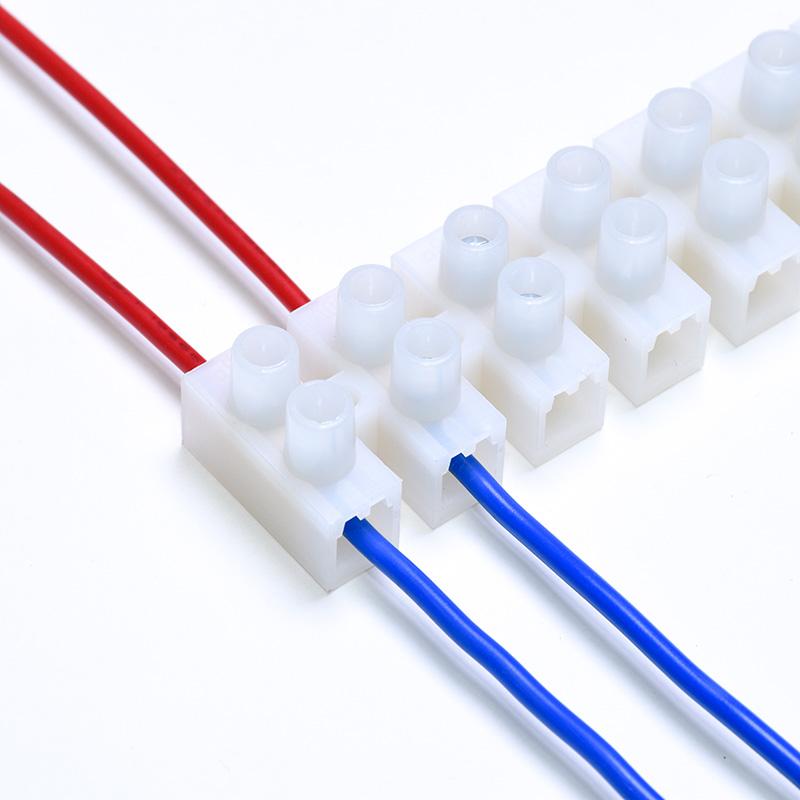

Nylon Dual Row Terminal Strip Connector are designed for industrial applications, especially where enhanced connection durability and increased resistance to weather conditions are essential. Each strip has 12 circuits and can be easily cut to the required number of poles. All metal parts are completely recessed in the flexible polyamide moulding. This dead front design ensures safety and prevents short circuiting.A key feature is the use of Polyamide PA 6 for the body material and a brass clamp with a galvanic coating to improve corrosion resistance.

|

ItemNo |

MJTB001-30-38 |

|

Contact Material |

Brass |

|

Termination Method |

Screw Down |

|

Glow Wire Test |

850 ℃ |

|

Material |

Polyamide6 Housing |

|

Number of Ways |

12 |

|

Inserts |

Brass |

|

Housing |

Polyamide6 (PA6) |

|

Screws |

Steel,Zinc plated |

1. Insulated Flame-Retardant Shell: These dual row terminal strip connectors feature a flame-retardant PA6 material shell, providing insulation, corrosion resistance, and wear resistance. Dual row terminal strip connector can withstand hitht temperature and offer excellent electrical conductivity.

2. Superior Crimping Performance: Equipped with plated zinc screws,these dual row terminal strip connectors ensure outstanding stability and conductivity, providing long-lasting service.

3. Easy Installation: Simply strip the wires, insert them into the terminal strip, and tighten the screws—no need for troublesome welding. Additionally, you can easily cut the screw terminal block into smaller parts using scissors or other tools.

4. Safety First: The set screws secure wires with reliable contact, helping to prevent accidental contact with the terminals.

Nylon Dual Row Terminal Strip Connector General Specifications

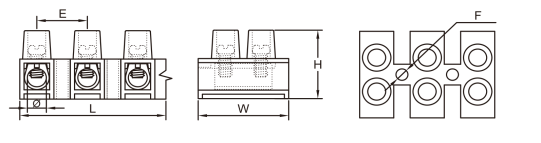

| ltem No. | Wire Range | Amp | Volt | L | W | H | E | F | Ø | Screw Size | PCS/CTN |

| mm | |||||||||||

| MJTB001-30 | 2.5-4.0mm² | 3A | 400V | 95.3 | 17.5 | 13.0 | 8.0 | 2.5 | 3.0 | M2.5 | 1000 |

| MJTB001-31 | 4.0-6.0mm² | 6A | 400V | 117.4 | 19.0 | 15.5 | 10.0 | 2.6 | 3.3 | M3.0 | 800 |

| MJTB001-32 | 6.0-10 mm² | 10A | 400V | 132.6 | 21.2 | 16.6 | 11.0 | 2.9 | 4.2 | M3.0 | 500 |

| MJTB001-33 | 10-12mm² | 15A | 400V | 142.0 | 23.2 | 19.0 | 11.8 | 3.2 | 4.5 | M3.5 | 400 |

| MJTB001-34 | 12-14mm² | 20A | 400V | 141.5 | 23.4 | 20.4 | 12.2 | 3.2 | 4.5 | M4.0 | 400 |

| MJTB001-35 | 16mm² | 30A | 400V | 169.0 | 26.1 | 20.5 | 14.2 | 3.4 | 5.5 | M4.0 | 300 |

| MJTB001-36 | 25mm² | 60A | 400V | 192.0 | 30.0 | 26.0 | 16.2 | 3.4 | 6.5 | M4 .0 | 160 |

| MJTB001-37 | 35mm² | 80A | 400V | 233.5 | 37.0 | 29.8 | 20.0 | 3.8 | 8.0 | M5.0 | 100 |

| MJTB001-38 | 40mm² | 100A | 450V | 262.0 | 46.0 | 35.7 | 22.5 | 4.1 | 9.0 | M6.0 | 50 |

Nylon Dual Row Terminal Strip Connector are perfect for linking lighting lamps, household appliances, electrical control systems, power supplies, electrical maintenance, electrical machinery, and more.

Our hours