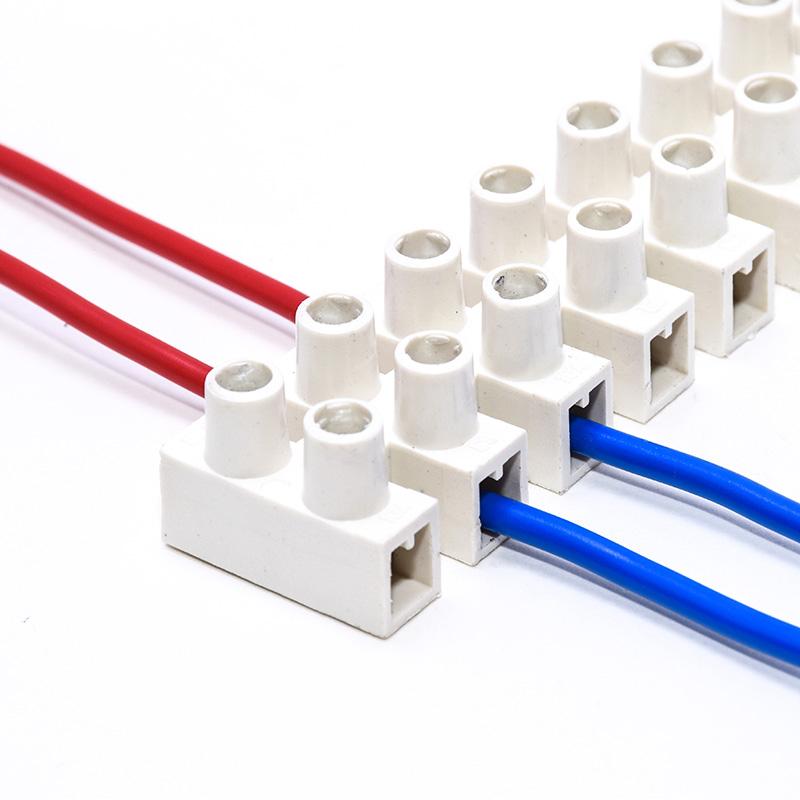

Power Flexible Wiring Terminal Strip with wire protection are fitted with a wire protection guard inside the clamping body, which prevents damage to the connected wire. All parts are captive in the insulating housing.

|

ItemNo |

MJTB006-01-04 |

|

Contact Material |

Brass |

|

Termination Method |

Screw Down |

|

Glow Wire Test |

850℃ |

|

Material |

Polyamide6 Housing |

|

Number of Ways |

12 |

|

Inserts |

Brass |

|

Housing |

Polyamide6 (PA6) |

|

Screws |

Steel,Zinc plated |

Advantages of Power Flexible Wiring Terminal Strip

1. Wide Wire Compatibility: Suitable for connecting stripped, unterminated, solid depending on the selected product.

2. Customizable Strips: Each strip contains 12 circuits and can be easily cut to the desired number of poles.

3. Convenient Mounting: Mounting holes are provided between each circuit for easy installation.

4. Ready for Wiring: Captive screws are pre-loosened and ready for immediate wiring.

5. Wire Protection: Each circuit is equipped with a wire protector to prevent damage from turning screws.

6. Safety Design: All metal parts are fully recessed in flexible polyamide molding, ensuring a dead front design that prevents short circuits and enhances safety.

Application of Power Flexible Wiring Terminal Strip

Power Flexible Wiring Terminal Strip deal for applications with line voltage motors and construction vehicles. They are also perfect for use in heating, ventilation, and air conditioning (HVAC) products, ensuring reliable performance in demanding environments.

Power Flexible Wiring Terminal Strip General Specifications

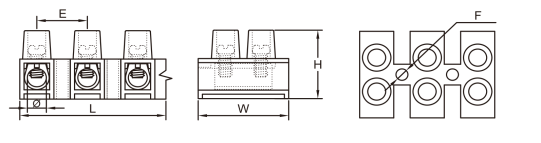

| ItemNo. | Wire Range | Amp | Volt | L | W | H | E | F | Ø | Screw Size | PCS/CTN |

| mm | |||||||||||

| MJTB006-01 | 2.5mm² | 3A | 450V | 94 | 17 | 7 | 8 | 3 | 3 | M2.5 | 1000 |

| MJTB006-02 | 4.0mm² | 6A | 450V | 117.5 | 20 | 15 | 10 | 3 | 3.2 | M3.0 | 1000 |

| MJTB006-03 | 6.0mm² | 10A | 450V | 140 | 23 | 17 | 12 | 4 | 4.2 | M3.5 | 500 |

| MJTB006-04 | 16mm² | 30A | 450V | 175.7 | 26 | 22 | 15 | 4 | 5.5 | M4.0 | 500 |

Our hours