About Us

Innovative and Reliable Cable Connection Solutions from MJ

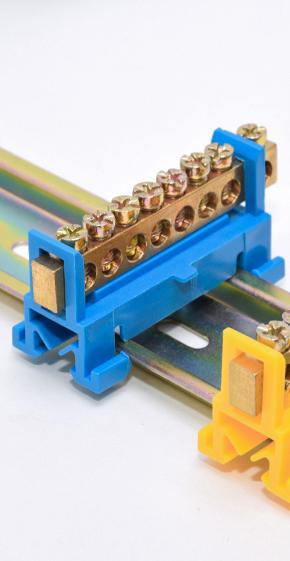

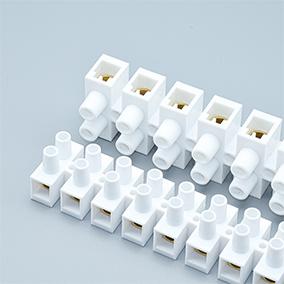

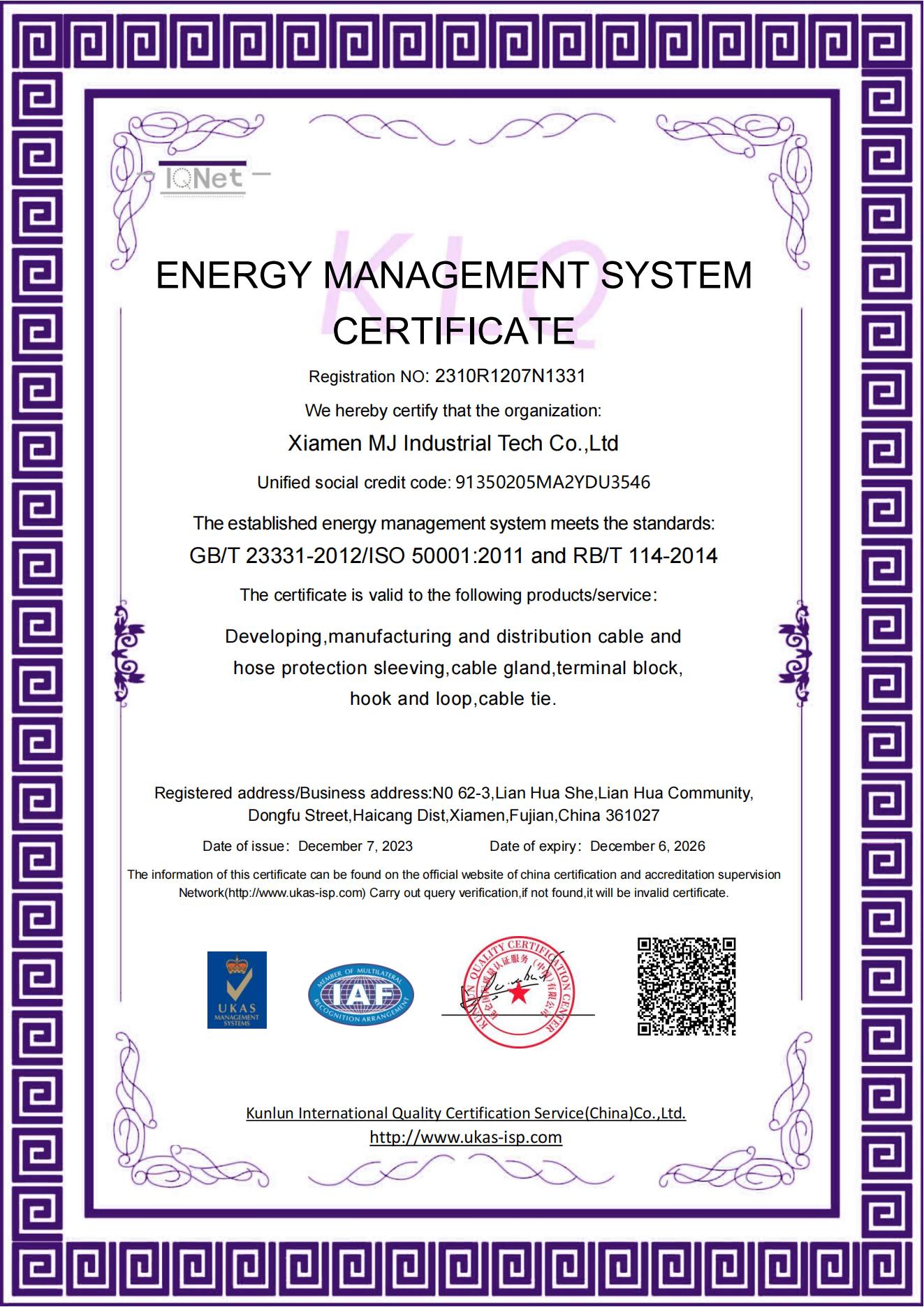

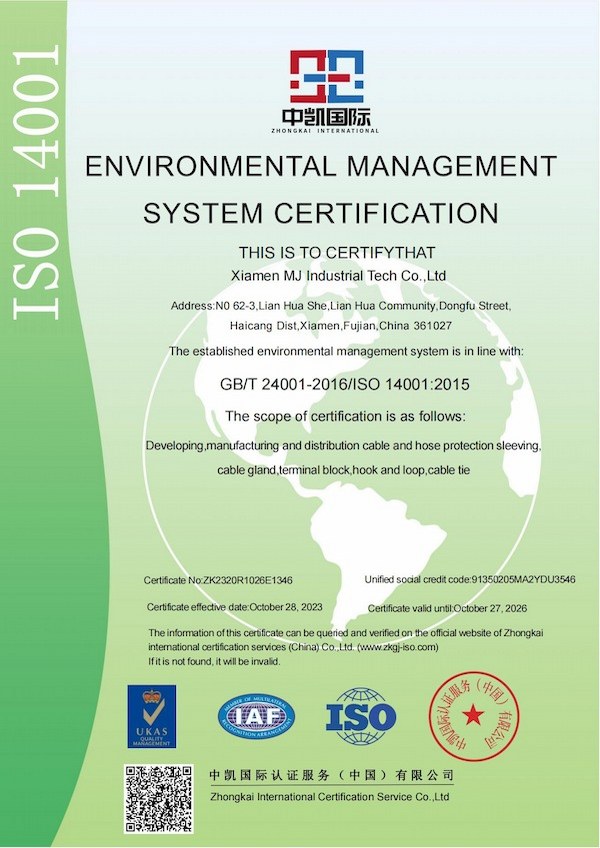

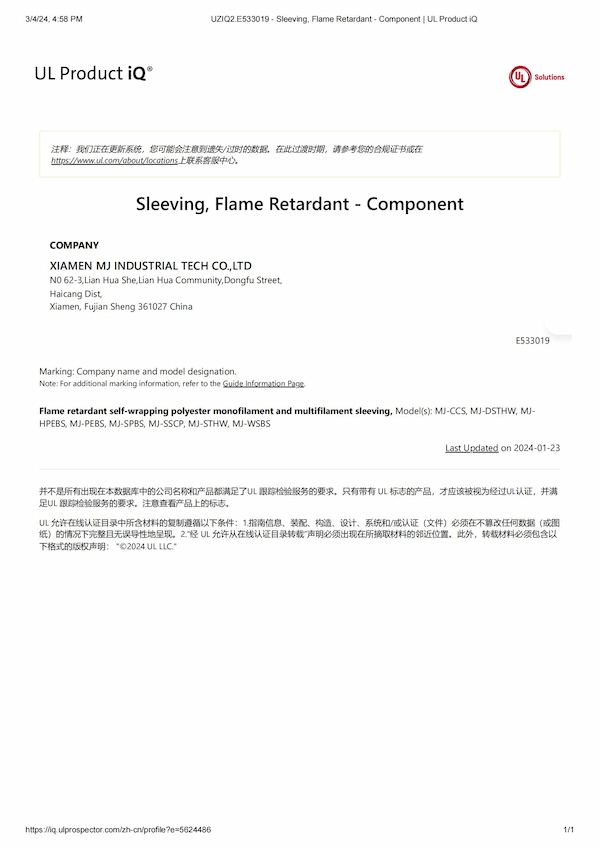

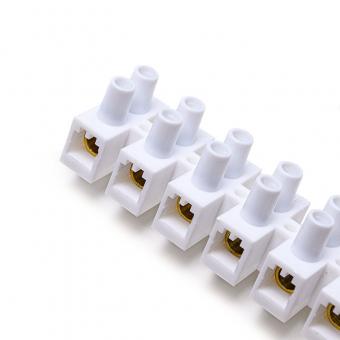

MJ Is an independent, privately owned company with headquarters in Xiamen,on the Southeast of China,And MJ is a reliable supplier of innovation,Safer, efficient,Sustainable, Productive cable connection solutions that focuses on the development, production and commercialization of innovative terminal blocks and other specialty connectivity solutions for various industries across the globe.We work with innovative, cutting-edge cable connector,terminal block manufacturers ,we is able to advise customers on the latest trends in technology as well as sharing product roadmaps.Whether it’s in materials that improve performance and reduce cost or developing products to meet the changing needs of the market, we have your solution.

Partnering with MJ Engineers and Product Specialists

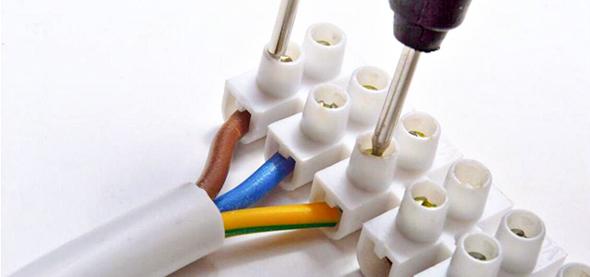

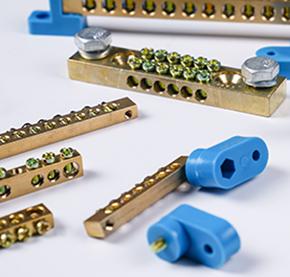

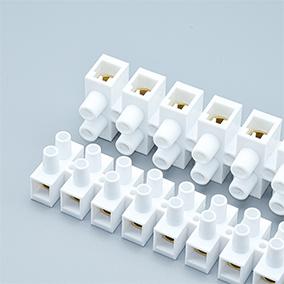

MJ engineers and product specialists have partnered with customers to produce highly reliability, durability terminal block,cable connector,cable gland and other connection accessoriesOur products are ideal for various industrial applications such as industrial automation, machine building, logistics, lighting, and power distribution,energy & power management, fire & security etc.

Exceptional Service and Reliable Solutions with MJ

We take pride in providing our customers with excellent customer service, custom design options, and reliable delivery and lead times. We’re committed to making your next order stress-free.Let’s work with MJ, Creating Satisfied Connections for better life,for tomorrow together!

Read More

English

English  français

français  Deutsch

Deutsch  русский

русский  italiano

italiano  español

español  português

português  العربية

العربية  română

română  היברית

היברית

Contact Us

Contact Us IPv6 network supported

IPv6 network supported